>>SPM-M Kit

Additional Information

AFM Video Tutorial

MadPLL® Brochure

Laser Focus World Article

Sensor Probe Board Drawing

Related Products

SPM Accessories

MadPLL®

Tuning Forks

Nano-OP Series

Nano-SPM200

Nano-HS Series

Nanopositioning Accessories

Nano-Drive®

Questions?

E-Mail Us

Introduction

|

Absolute MetrologyThe SPM-M Kit incorporates the Nano-SPM200 and Nano-OP30 with a three axis Nano-Drive® controller for closed loop nanopositioning in X, Y, and Z. These systems incoporate Mad City Lab's proprietary PicoQ® sensor technology for closed loop feedback control, offering significant advantages in terms of image quality, accuracy and repeatability over open loop scanners. The sensor signal from all three axes can be read during AFM scans via the analog output signal or USB, thus minimizing the effects of hysteresis, curvilinear motion, and creep that result if data are analyzed using assumed commanded positions. Using position information from closed loop sensors also eliminates the need to scan a calibration grid in XYZ before scanning every sample. Scanning with closed loop nanopositioners saves time and improves image quality. Closed loop feedback also allows the nanopositioners to move and return to commanded positions with much more reliability than open loop systems, allowing users to return to previously scanned features for further analysis. For further information about the PicoQ® sensors used in Mad City Labs piezo nanopositioning systems, see the PicoQ® sensor technology page and our Technical Information pages. |

AFM Video TutorialInstant AFM - just add science!The video at the page linked below illustrates how to use the SPM-M kit along with an Akiyama Probe, manual coarse positioners, and hardware to create a low cost, easy assembly, high resolution AFM.

|

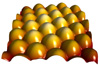

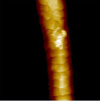

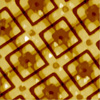

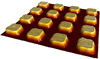

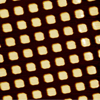

Image GallerySeeing is Believing!The images below were acquired using similar configurations to the SPM-M Kit.

|

Tungsten Tip Etching with the SPM Etch Kit An etched tungsten tip glued to a quartz tuning fork. One way to produce sharp probe tips suitable for building an AFM is to electrochemically etch tungsten wire. This method can produce a tip radius of better than 50nm. Post etching techniques can even sharpen the tip down to a <1nm tip radius. These sharp tungsten tips can be mounted to quartz tuning forks for AFM or for other types of scanning probe microscopy like scanning tunneling microscopy (STM). There are a variety of methods to choose from to etch the tungsten wire. The single lamella technique is easy to setup and can consistently produce sharp tips. Among the requirements for this process are a metallic ring, a beaker, Potassium Hydroxide (KOH), tungsten wire, and a voltage source. A drop of KOH is added to the metal ring suspended above the beaker, forming a thin film or lamella of KOH inside the metallic ring. The negative terminal of the voltage source is then connected to the suspended metallic ring. This will form the negative electrode. The beaker below the ring is then filled with KOH and the positive terminal of the voltage source is wired intod the KOH solution. This forms the positive electrode. The tungsten wire is then dipped through the center of the lamella and into the KOH in the beaker. The voltage source dis then turned on which begins the etching process. The tungsten is electrochemically etched at the lamella. The etching process automatically stops when the tungsten wire is etched so thin that the portion of wire below the lamella falls off and drops into the beaker. The remaining tungsten wire above the lamella is removed and any remaining KOH or contaminants are rinsed off with distilled water. This leaves a very sharp tip suitable for use in AFM or other types of SPM. Mad City Labs provides an SPM Etch Kit along with an application note on etching Tungsten tips to make this easy. |

Additional Information | ||

MadPLL® Brochure |

Laser Focus World Article  NANOPOSITIONING: Piezoelectric nanopositioners forge low-cost atomic force microscope |

AFM Video Tutorial |

MadPLL® Sensor Probe Board Drawing  |

Application Notes:

SPM-004 "Building an AFM with motorized XYZ and camera" | |

Related Products |

Copyright © 2024

The SPM-M Kit combines the

The SPM-M Kit combines the  Mad City Labs AFM Assembly Tutorial - How to Build an "Instant" Atomic Force Microscope

Mad City Labs AFM Assembly Tutorial - How to Build an "Instant" Atomic Force Microscope